Stream finishing machine SF 1 ILS

The solution of choice for processing small workpiece batches and frequently changing series.

The solution of choice for processing small workpiece batches and frequently changing series.

Equipment:SF 1 |

TECHNICAL DATA

A chain loader on the SF 1 ILS fi tted with tool |

We get you to the finish with μ precision.In series production, reliably repetitive results and costeffectiveness deliver a real competitive edge.

Precision finishing

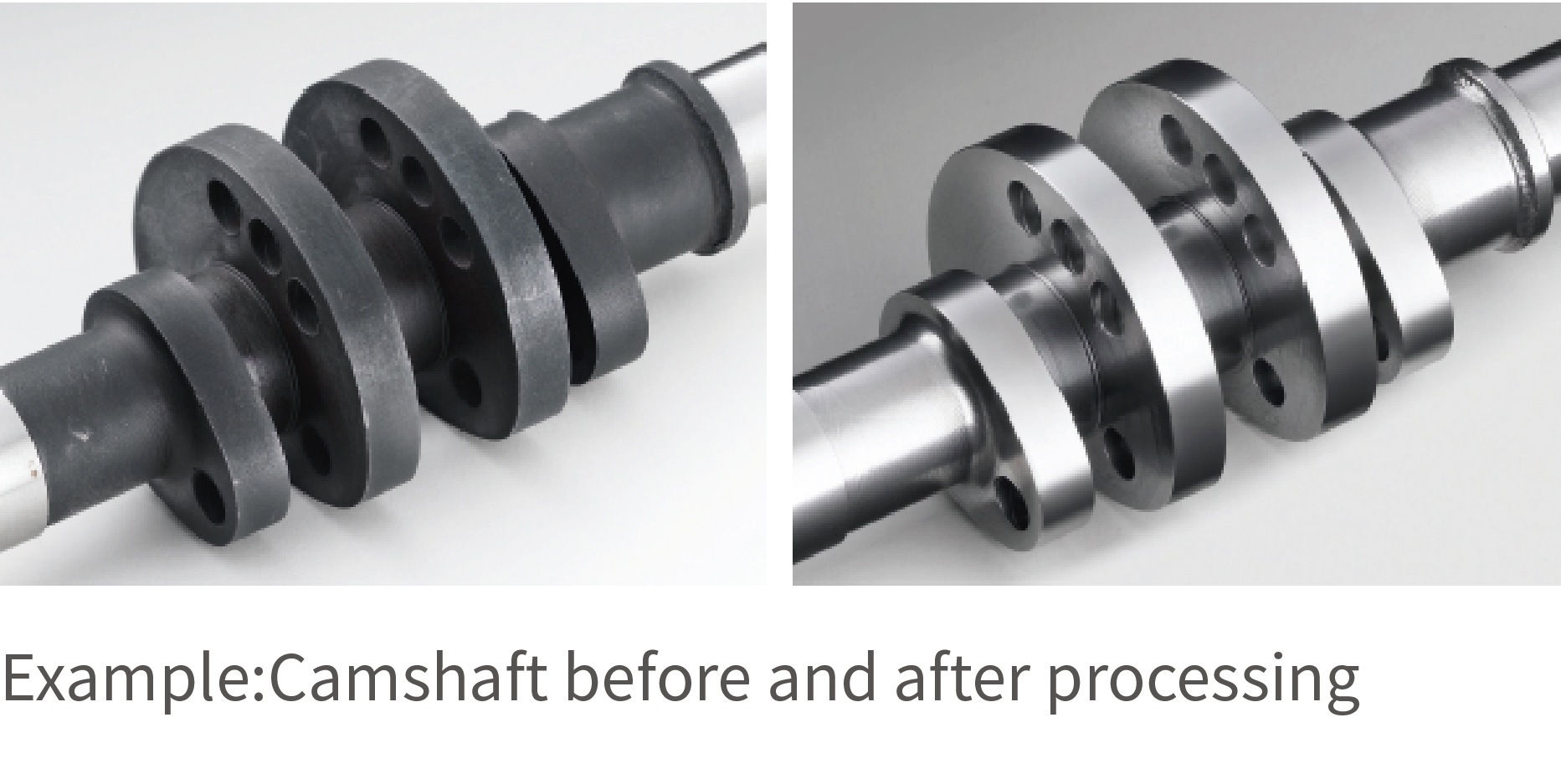

This fast mass fi nishing process ensures extremely short process times, even with complex shapes. Parts can be deburred, rounded, smoothed or polished in a single work step. This process also effortlessly achieves roughness depths of far below 0.1 μm.

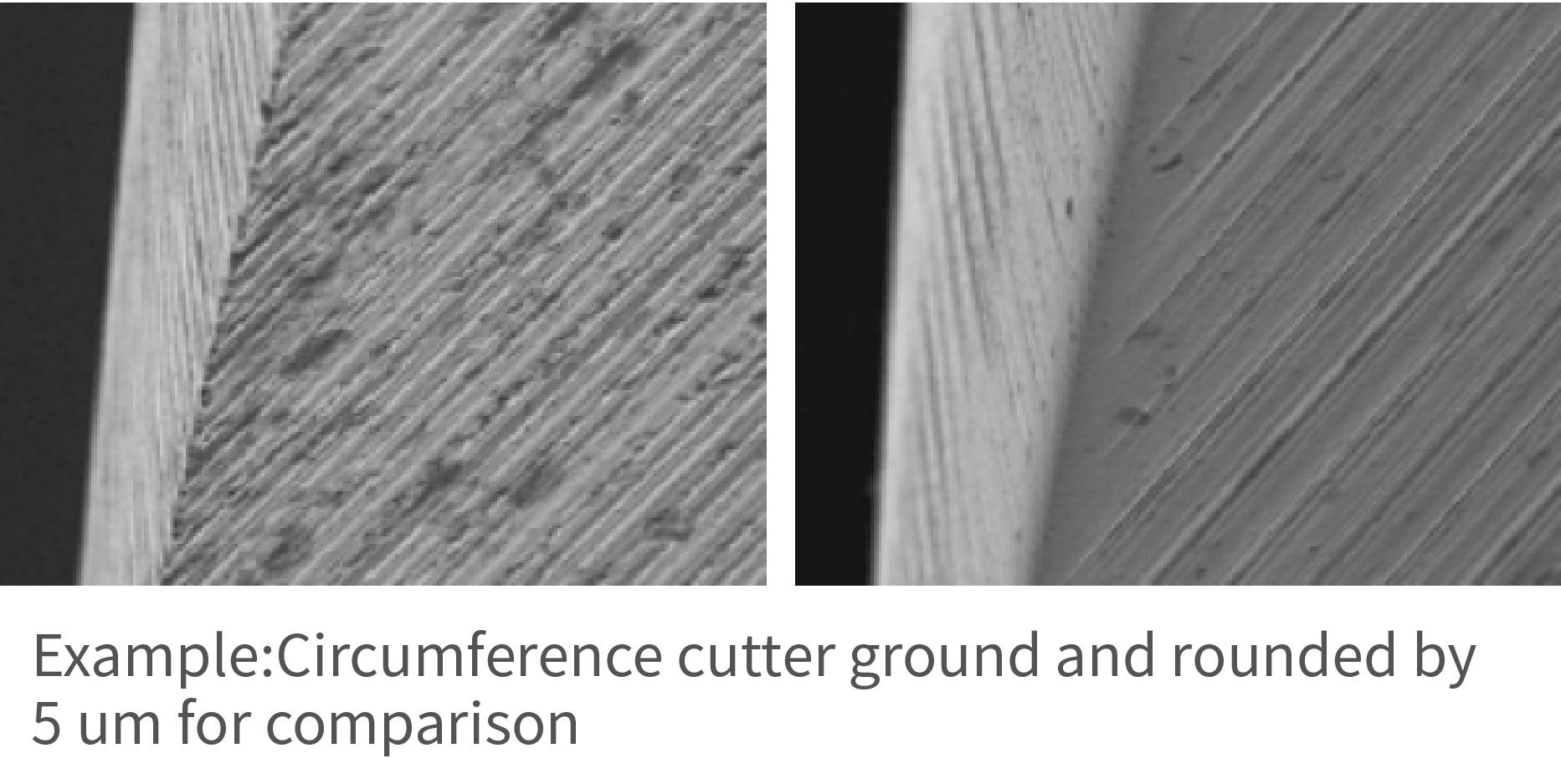

Rounding cutting edges

Rounding a tool’s cutting edge by even a small amount like 15 μm can stabilise the edge and ensure a perfect, burr-free geometry. This protects the edge against breakages and signifi - cantly improves both the service life and process reliability of the tool.

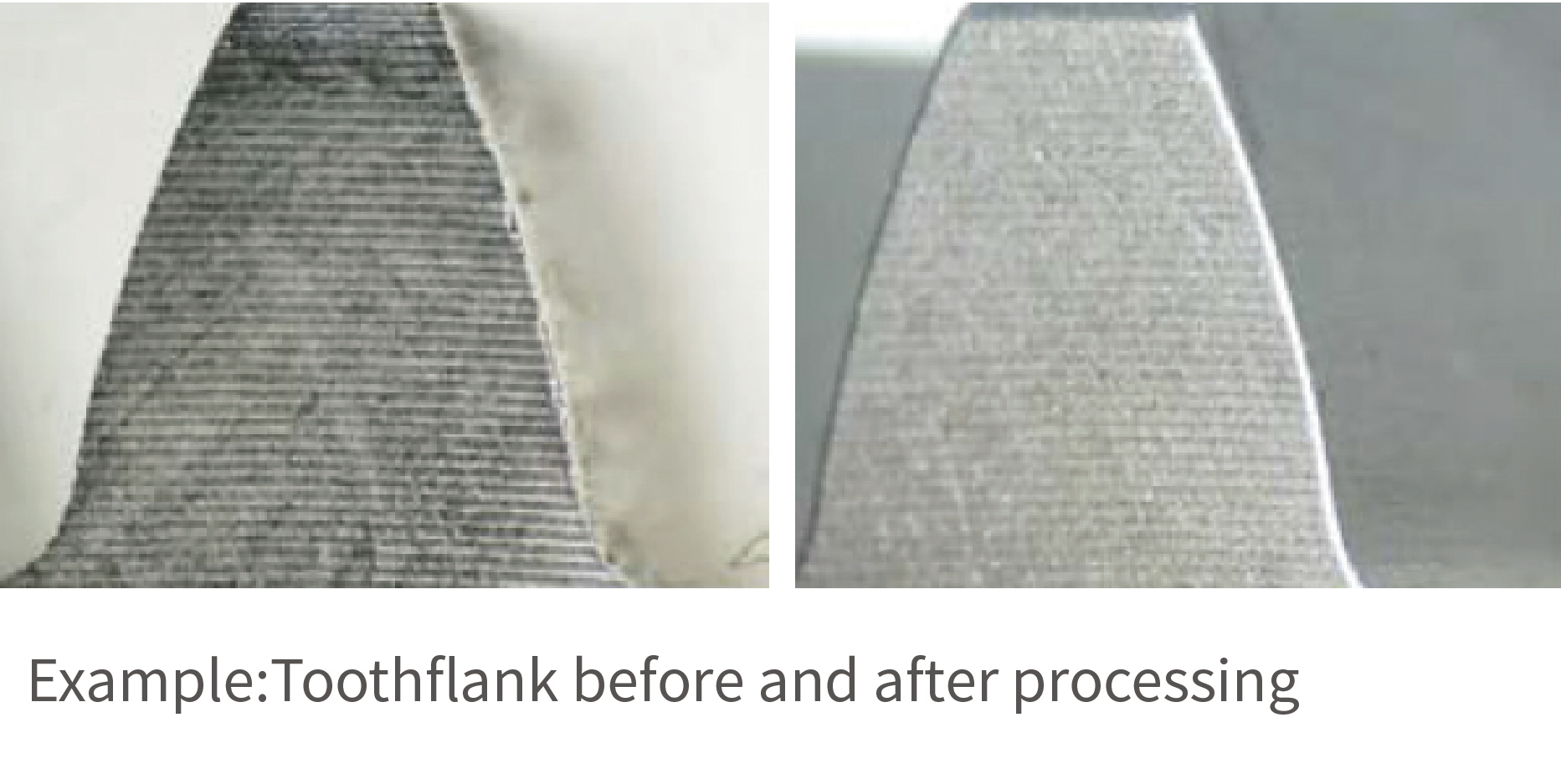

Smoothing

With smoothing, the roughness of the surface is reduced, i.e. the unevenness in the peaks on the surface are removed. The benefits this brings include reduced friction, higher contact ratios and less wear. A further benefit is the removal of droplets after PVD coating.

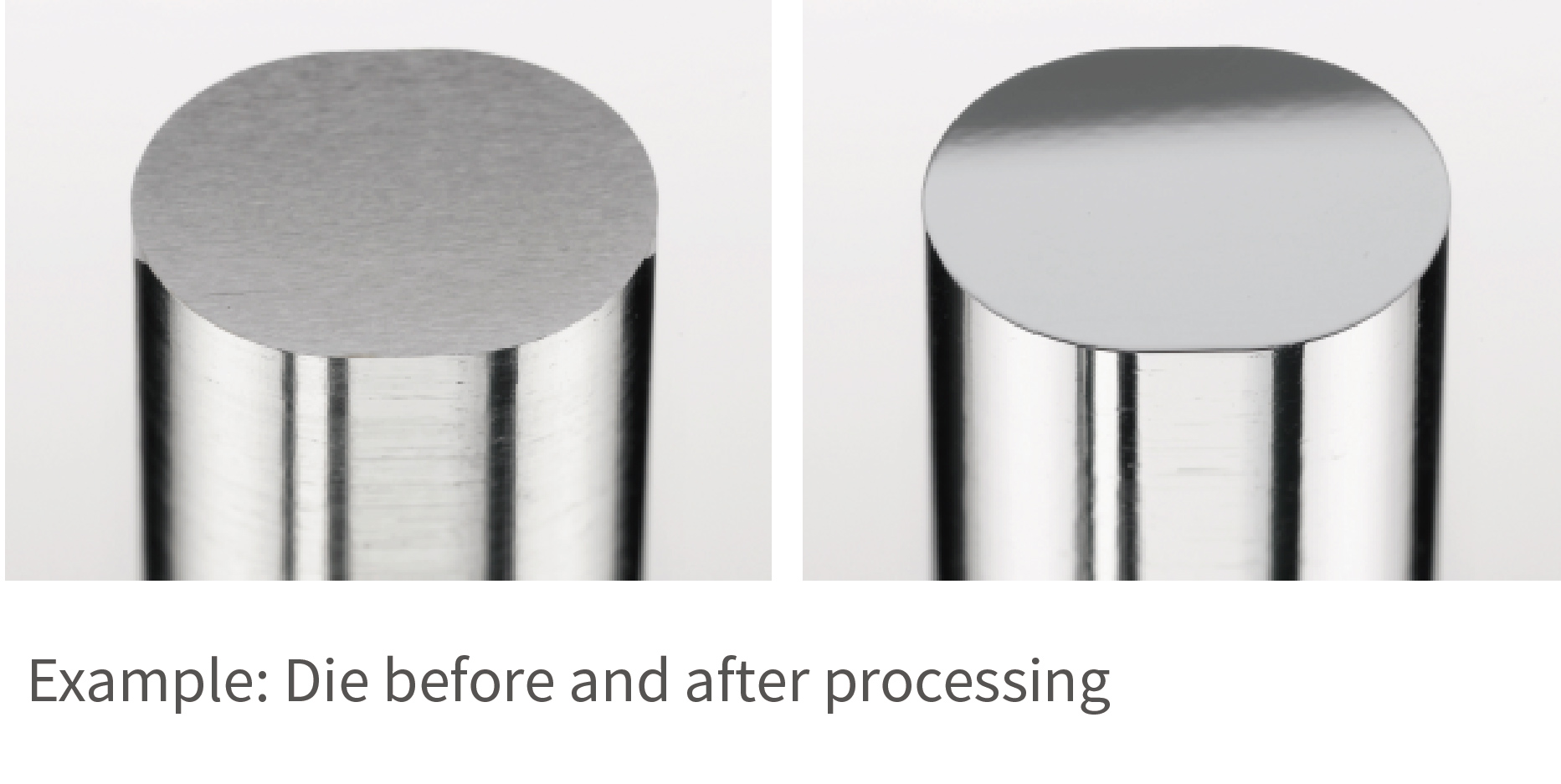

Polishing

In addition to improving the appearance of the workpiece surface, polishing also improves the physical properties of the surface. A polished chip fl ute on carbide cutters and drill bits can increase the maximum cutting speed, for example, as well as boosting coating adhesion. A polished forming die will have a longer service life and lower friction coeffi cients.

ZOTEC stream fi nishing machines offer versatile, fl exible and effi cient surface fi nishing for small or large series production. If required, they can be fi tted with the right automation systems for every application.

By choosing an OTEC SF, not only are you choosing uncompromising German quality, but a secure future too.With a comprehensive range of standard equipment, optional extras and countless automation choices, our machines help you scale your production.

You can increase operating comfort and process reliability further with optional modules. Immersion depth control, for example, controls the immersion depth of the workpiece depending on the process. It can be programmed either manually or fully automatically. Wet processing machines feature a dosing unit that allows users to adjust the compound concentration via the touch panel.

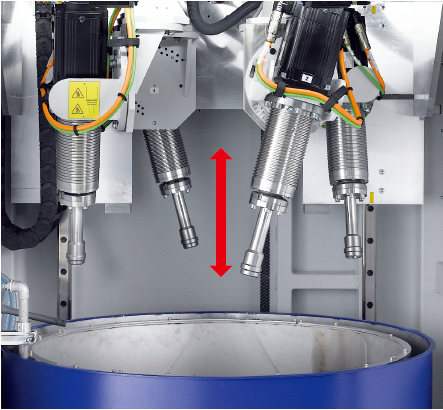

Variant 1: Decentralised lifting unit

Here, all holders and workpieces are immers ed simultaneously. This version is mostly used with manual loading and unloading.

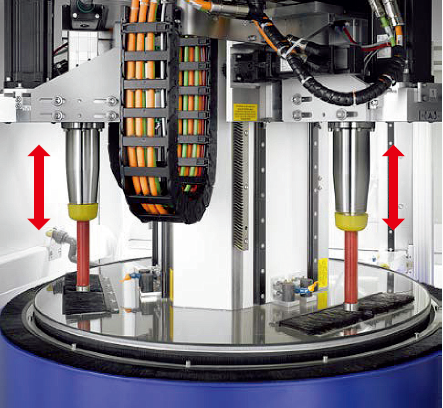

Variant 2: Centralised lifting unit

All lifting units are immersed individually. One workpiece is changed while the others are processed. This variant results in shorter downtimes and is mostly used with automatic loading and unloading.