Front flap door which is operated with cylinders, supported by compressed gas, can be opened up to the working height of the microblasting equipment, with integrated sight window with a safety and an attrition-proof glass (double glass) in a quick change frame

Door interruption switch

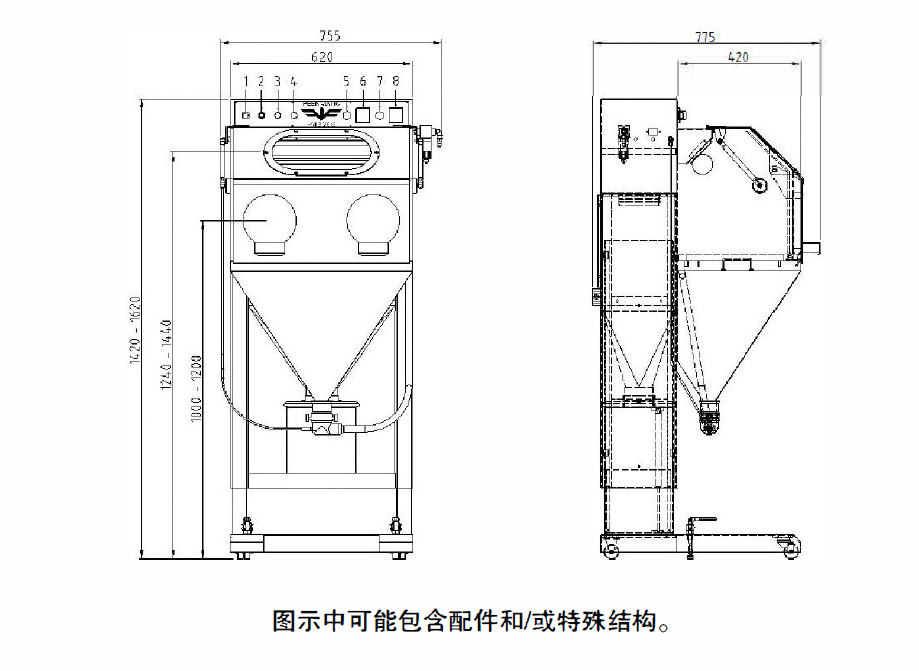

Manual, hydraulic adjustment of height (maintenance-free)

2-feet system with built-in rollers, moveable, can be locked manually

Working grate made of perforated plate, one-piece, detachable, diameter of holes 5 mm

Padded sleeves and gloves, exchangeable

Microblasting pistol unit, type EF 3, with hard metal blasting nozzle HSD 5/10,

adjustable via pressure reducing valve, 0 - 8 bar, microblasting pressure reading on the manometer

Continuous drying system for microblasting agents, 50 W, electronically continuously

adjustable, including covering for heating element

Microblasting agent pre-accelerating system with moving injector, adjustable via pressure

reduction valve, 0 - 4 bar, pressure reading on the manometer

Automatic, selective microblasting agent recycling system, type SHOT SEPARATOR

Built-in high surface microfilter system with one filter cartridge with 0,64 m2 filter surface. Automatic, electro-pneumatic filter cleaning

Dust collector, made of steel

Ventilator for high surface microfilter unit, electronically continuously variable

Blow-out pistol (air-blasting pistol)

Foot actuated switch with impulse contact

Compressed-air connection, 1/4", at equipment, including oil and water separator

Control panel with all necessary switches and control elements

Main switch, on / off, with 2 keys

Illumination